To make reinforced concrete, you use steel reinforcement bars to give strength.

To make reinforced concrete, you use steel reinforcement bars to give strength.

Engineers use reinforced concrete in a number of ways, for floors, walls, and other structures.

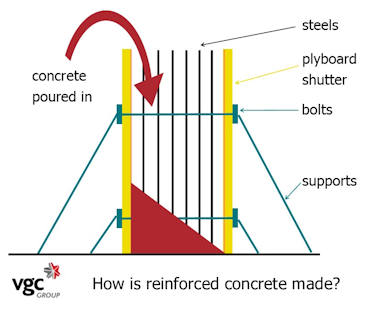

This example is based on a wall.

- Start off with steels, which are ordered to meet the engineering specifications for the structure.

- Steelfixers use engineering drawings to put the steels together in a frame which will eventually be the steel reinforcement in the wall.

- Then shuttering carpenters fix sheets of treated plyboard on the outsides of the frame. They’re carefully bolted in place.

- You end up with a ‘mould’ shape of the wall, with steel reinforcements through it. The forms have to be tied together and they are also usually supported with struts of various kinds to ensure that the structure is strong. Otherwise the weight of the concrete as it pours will push them apart.

- Then the concrete is poured into the mould.

- Concrete finishers smooth the concrete with floats to make sure it is flat and has a smooth surface. Concrete is corrosive, so there are strict safety rules about personal protective equipment (PPE) – see below.

- When the concrete has set (cured), the shuttering carpenters strike the plyboard – they take it off.

- The bolts that held it in place are removed, and any steel that still sticks out is cut off. Concrete finishers will fill any holes where the bolts have been pulled out, and make good, so it has a smooth surface.

Why would you want reinforced concrete?

Concrete is very strong if it is crushed, but it can crack if it is bent or stretched. To help it not to bend, steel (or plastic) reinforcement is put inside it. Steel is strong and won’t bend, but can be brittle. By forming concrete around steel reinforcement bars, it is much stronger. The steel is arranged inside it, protected from rust and fire by the concrete, and the two materials act together to carry the loads.

Concrete hardens (cures) over a few days – it actually takes in water, rather than ‘drying out’. The longer it takes to cure, the stronger it is.

At VGC our teams are involved in building reinforced concrete walls and floors for the platforms on Crossrail. Teams used reinforced concrete to build the Mersey Gateway cofferdams. The photo at the top of this page shows me watching a concrete pour on the M1 junction 19 Catthorpe interchange project. Other teams have built hardstandings for the overhead gantries for elecrification of rail, or for smart motorways.

What’s the difference between concrete and cement?

Cement is one of the ingredients used to make concrete. If you mix sand and gravel or crushed stone with a paste of water and portland cement, you get concrete. Just do it carefully and wear the correct PPE – see above: concrete is corrosive, and you don’t want to touch or breathe it in.

PPE

Concrete is dangerous. As well as asking people to be careful on site, we also insist that they wear proper PPE. Waterproof boots and strong coveralls, and special fully waterproof coated gloves, make sure people don’t touch the concrete – it would burn their skin badly.

People working with concrete also wear face-fitted dust masks to ensure they don’t breathe in cement or the corrosive silica dust. Our HSQE teams regularly test that people are fitting their masks correctly.