Ben writes:

We carry out regular face-fit testing on our projects.

The test makes sure that anyone who has to wear RPE (respiratory protective equipment) knows how to fit it correctly.

If you are working in a dusty environment you are at risk of breathing in dangerous dust particles. You will be given the correct RPE – on most of our sites, that is a dust mask. As long as you wear it correctly, it will protect you from inhaling dust particles which can damage your lungs.

However, you must fit it correctly on your face so it creates a seal.

The training makes sure people know how to fit their masks correctly.

For example, I’ve been carrying out the face-fit tests on everyone working on the M4 project, including workforce from Balfour Beatty, Danny Sullivan, Fortel, Zone and Hercules Site Services as well as VGC operatives. The training reduces the risk that anyone on the project will get ill from working in construction.

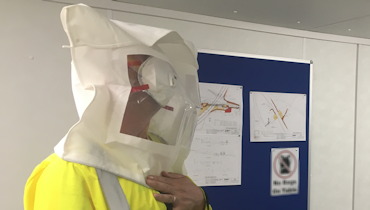

How the test works

Workers fit their dust masks as usual, and then put on a hood over the top. I spray denatonium benzonate, a bitter-tasting chemical, into the hood. (The taste is unpleasant but not harmful.) As long as the mask is properly fitted, they don’t taste it at all.

Respiratory protective equipment is part of your personal protective equipment (PPE). You must always wear the proper PPE for the task. The works on the M4 include concrete works. Concrete dust contain silica, and breathing in silica can cause scar tissue on the lungs, called silicosis (link to NHS website). So checking the fit of dust masks controls the risk of long-term damage – time very well spent.